PVD control system BPC-380 for belt conveyor

product description

The control system is controlled by Siemens or AB’s original PLC, equipped with a high-definition touch screen, which can control the start/stop of permanent magnet motors, frequency converters, water-cooled motors and cooling fans (water-cooled motors need to be equipped with electromagnetic starters). Collect temperature signals of permanent magnet motors and cooling devices, and interlock with the motor starting circuit to ensure safe and reliable operation of the belt conveyor. The control box reserves Ethernet and RS485 communication interfaces, which can transmit data with the frequency converter, integrated protection system, belt conveyor main control system, and integrated automation system.

The touch screen displays the operating status of the belt conveyor in real time, mainly including the following screens:

Ø Main monitoring screen

The operation overview of the belt conveyor, including the main motor current, speed, motor temperature, and monitoring of the operation of each auxiliary motor;

Ø Fault alarm screen

Real-time display of PVD system faults and alarm information, to help customers quickly locate fault points, timely analyze and deal with various software and hardware faults during operation;

Ø Parameter setting screen

According to the requirements of the on-site working conditions, timely modify the belt conveyor system parameters to meet the normal production conditions;

Ø Trend curve screen

The current and temperature curves of the belt conveyor motor are displayed in the form of trend graph;

Ø Other screens required by customers

Technical characteristics

Ø Comprehensive

The control box contains manual, automatic, remote, and on-site working methods, which can meet the needs of use under various working conditions on site;

Ø Compatibility

The control box supports multiple communication protocols such as Ethernet and RS485, and can communicate with the frequency converter, main control system, comprehensive protection system, and comprehensive automation system to reduce field wiring and reduce customer maintenance;

Ø Convenience

The HMI configuration screen adopts humanized design and parameterized design. Customers can adjust the operating characteristics of the system by changing the parameter settings of the touch screen to meet the needs of various production conditions;

Scope of application

Permanent magnet direct drive PVD control for belt conveyor in non-explosion-proof occasions, centralized control system for belt conveyor in non-explosion-proof occasions.

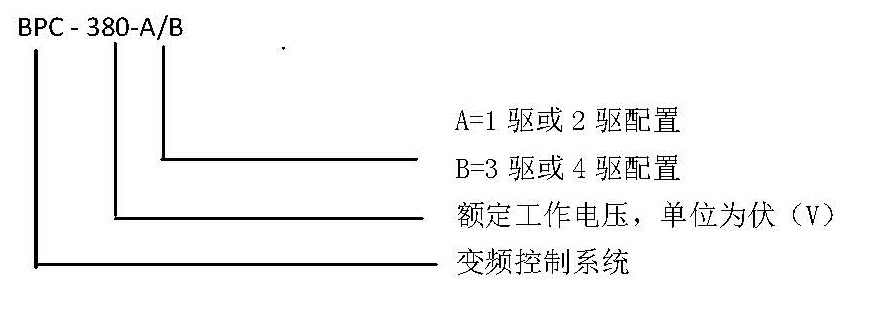

Model Description